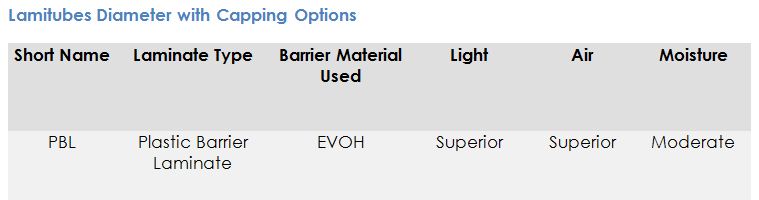

PBL (Plastic Barrier Laminates)

PBL tubes or Laminated Tubes are made completely of plastic with the barrier layer being made of Ethyl Vinyl alcohol (EVOH) plastic granules. EVOH is primarily used in applications where the packaging needs to look extra attractive, especially cosmetic products. Laminated Tubes made of all plastic layers can be completely transparent and make the final product packed inside the tube visible to the customers. These tubes are passed through conventional metal detectors.

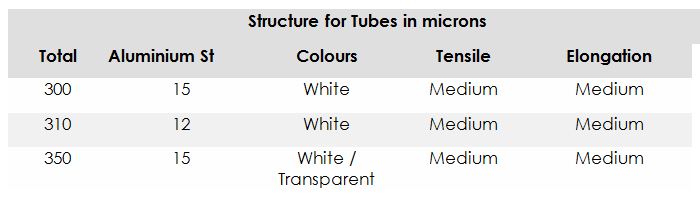

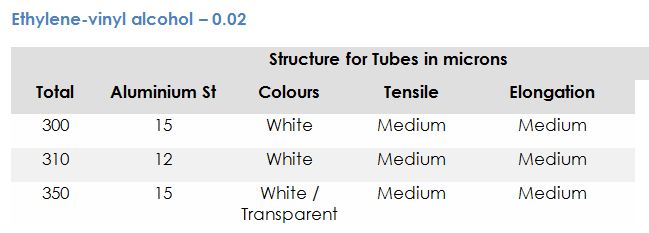

Laminate Structure: 300/15, 310/15 & 390/9.

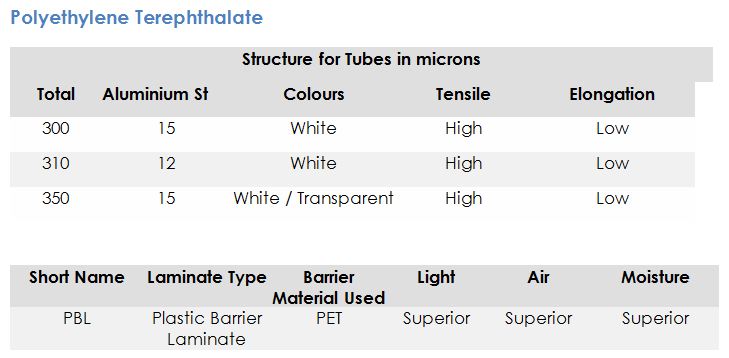

1. PBL Tubes (PET) Polyethylene Terephthalate

This is a 5 Layer film with PET in the middle layer. PET provides very strong barrier properties and is one among the most recommended barrier for plastic tubes. This is ideally suited to pack cosmetics both cream & gel based, food items and specific industrial chemicals having medium to high viscosity.

Oxygen & moisture being treat for any product, preservation is made easy with the use of this barrier.

Maximum Use temperature which PET can withstand is 204⁰ Celsius.

Oxygen Barrier: (cc /0.001 inch/100 inch 2/24 hr).

Polyethylene Terephthalate – 5.0.

Water Vapour Barrier: (g/1002 in/24 hr at 90% RH).

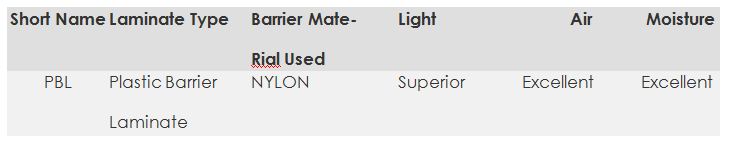

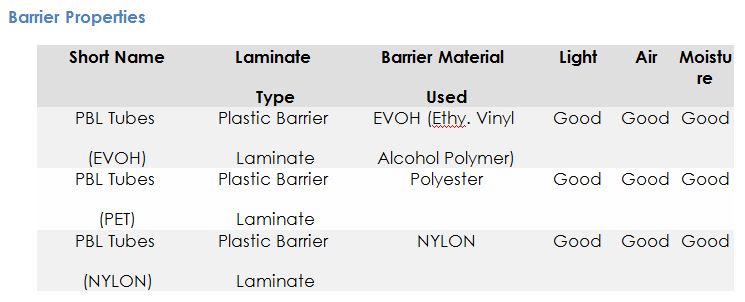

2. PBL Tubes (EVOH) Ethlylene Vinyl Alcohol Polymer

This is a 5 Layer film with EVOH in the middle layer. EVOH provides very strong barrier properties and is one among the most recommended barrier for plastic tubes. This is ideally suited to pack cosmetics both cream & gel based, food items and specific industrial chemicals having medium to high viscosity.

Oxygen & moisture being treat for any product, preservation is made easy with the use of this barrier. However, EVOH has a tendency to absorb moisture.

EVOH is ecofriendly and can be recycled easily.

Ethylene and Vinyl Alcohol (CH2-CH2)m, (CH2-CH)n OH

Oxygen Barrier: (cc/0.001 inch/100 inch 2/24 hr).

3. PBL Tubes (NYLON) Polyamide

This is a 5 Layer film with NYLON in the middle layer. NYLON provides very strong barrier properties and is one among the most recommended barrier for plastic tubes. This is ideally suited to pack cosmetics both cream & gel based, food items and specific industrial chemicals having medium to high viscosity.

Oxygen & moisture being treat for any product, preservation is made easy with the use of this barrier.

Maximum Use temperature which PET can withstand is 177⁰ celsius.

Oxygen Barrier: (cc /0.001 inch/100 inch 2/24 hr).

Polyamide – 3.0

Water Vapour Barrier: (g/1002 in/24 hr at 90% RH).

Polyamide – 25.0